How sharp are real Japanese Swords?

That question was asked in the Nihonto – Japanese Blades FB community and the answer of Kitaro Lodewijk was pretty interesting:

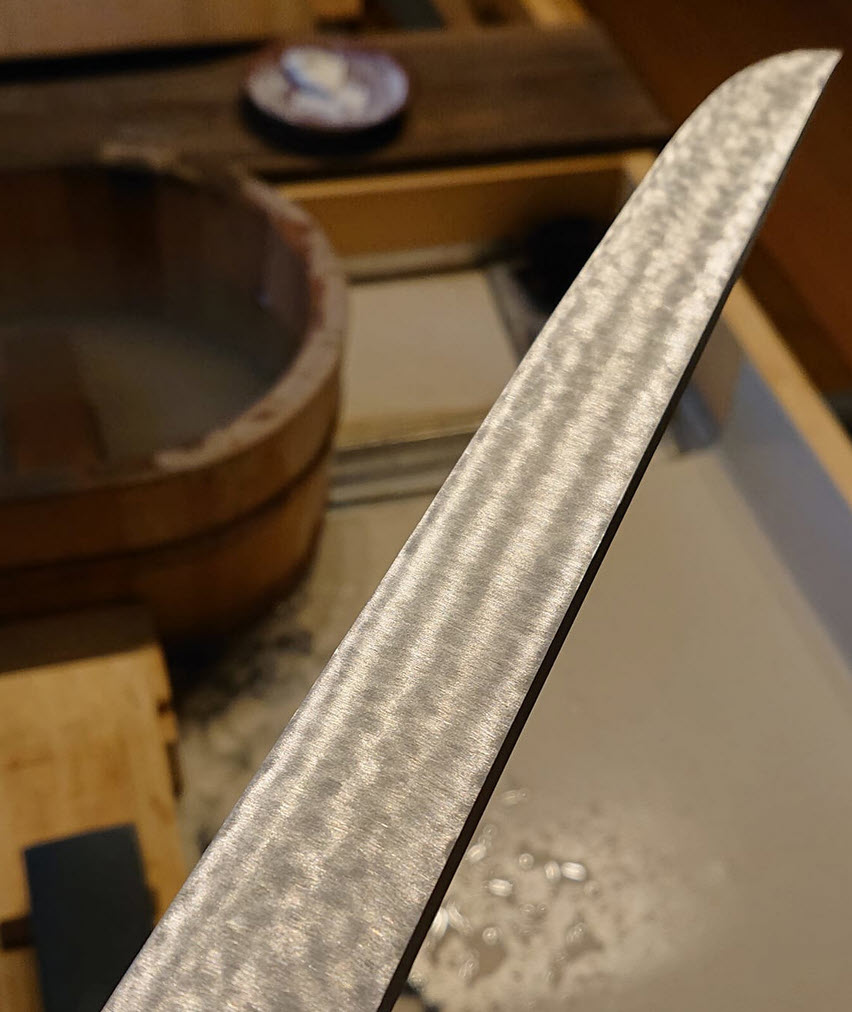

Japanese swords are not cut with the sharpness of the cutting edge, but with the curved surface of “平地 Hira-ji” that is called “肉置 Niku-oki (平肉 Hira-niku, 刃肉 Ha-niku).

If the cutting edge is sharp like a kitchen knife, the edge will be damaged (hakobore) and if the Hira-ji is flat like a kitchen knife, it will not cut through. When Katana hit the target, Hiraniku (curviness) open the target (to cut through.)

This ‘Nikuoki’ is the most important feature of the Japanese sword and to maintain(remain) the “Niku-oki” is the most important and special technic of the Japanese sword polishing.

When Hira-niku is polished out (to become flat surface) it has no value as a Japanese sword.

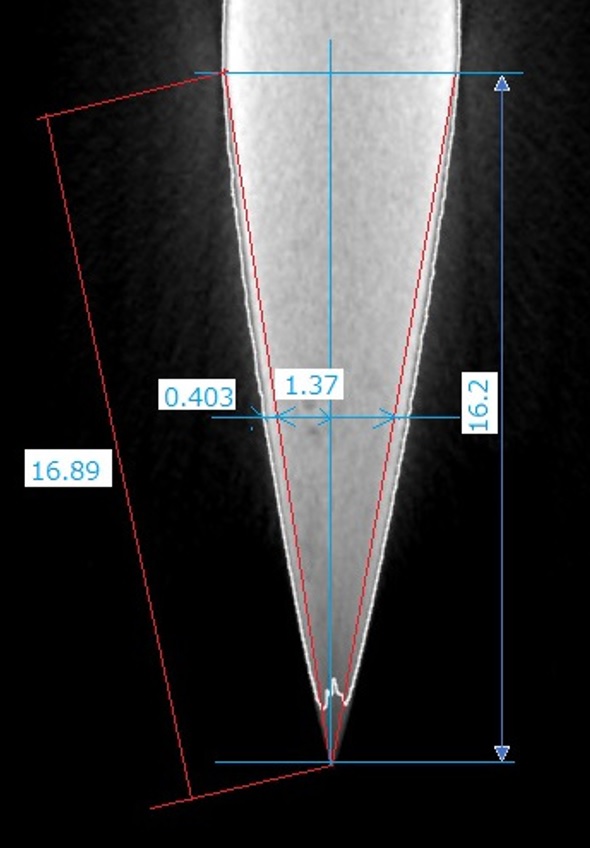

The image shown here below is the debris we prepared for the non-destructive inspection we are conducting. This is a cross-section scanner scanned with an industrial CT scanner, but with this machine you can measure スm (1/1000mm).The image is a part of the difference (2cm strong) and you can see that the flat meat is about 0.4mm.In addition, the curve from the nose to the tip is a uniform, and shows the level of training (or honesty) of the sharpener who polished the samples.

When the swords just polished (as an art sword), the cutting edge is very sharp, but, it is not practical to use.

There is called ‘盛砂 morisuna (or 立砂 tatezuna)’ which piled up sand like a mountain shape in the garden of daimyo-yashiki(house) or a shrine.

Those are to dull the blade by plunging the sword into the sand before using it.

In order to maintain the “Nikuoki”, polishing “切り kiri (90 degree angle to the stone) in the “Shitaji-togi”

It is more difficult and take time than polishing 筋違い Sujichigai (45 or more degree to the stone)

This is the standard 6-stripes, the Hon-ami is 12-stripes,

That is why polishing stone for Japanese sword is round, not flat for kitchen knife.

20-24 stripes are the master polish, (nobody does it nowadays)

Hon-ami Koson was the master of this.

However, Nowadays, many (Japanese) polishers skip this process, because. people want cheaper polish.

It is easier and faster to make sharp shape by polishing out Hira-niku,

It is difficult to see (recognize) Niku-oki by just photos on line.

Some people who don’t give attention about “niku-oki” are happy if the blade looks sharp with papers.